Blades

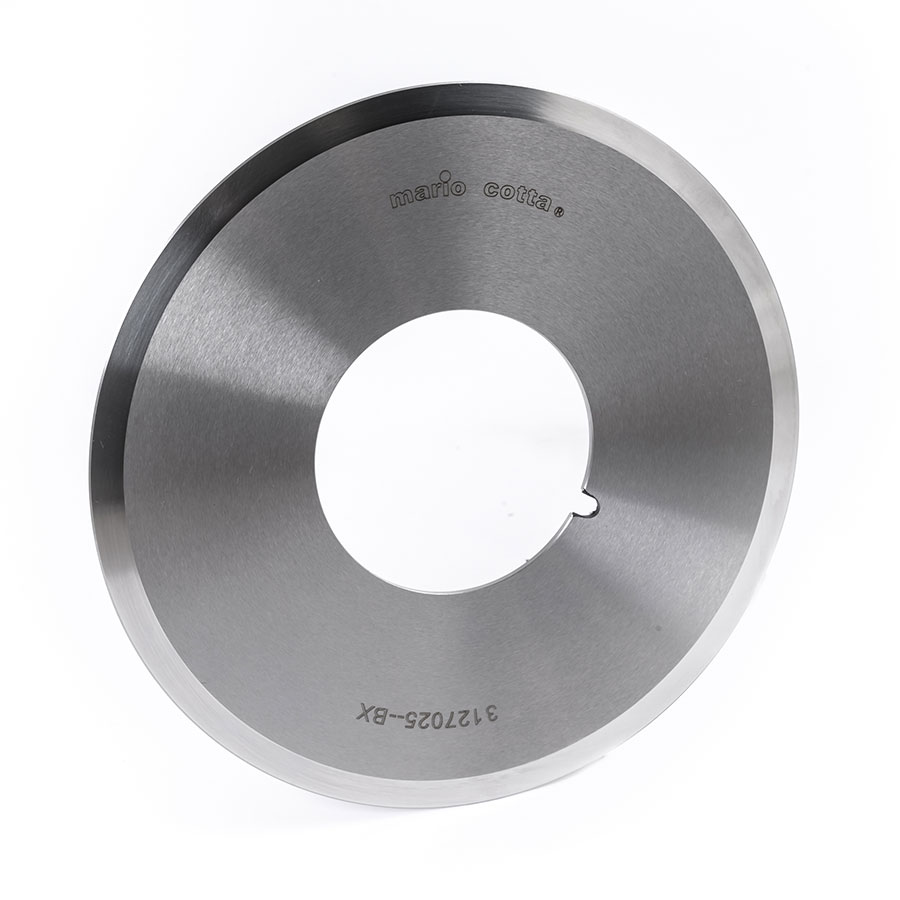

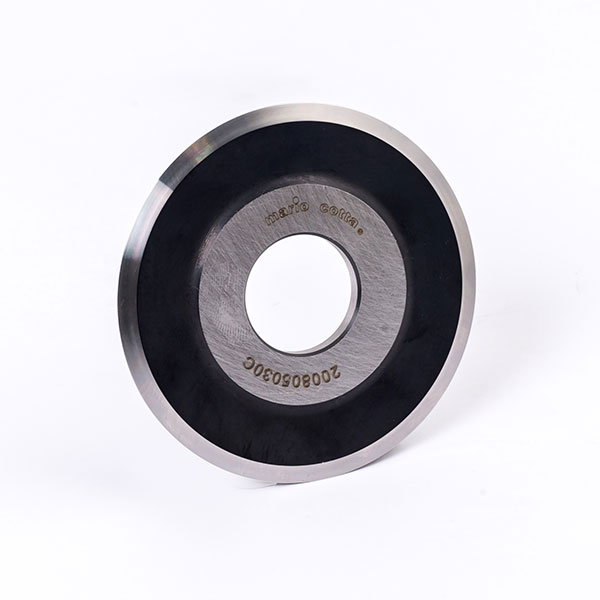

Circular Blades and Counter-blades for all applications

The division

Mario Cotta guarantees the highest quality to achieve the best cut. The production process is conducted entirely in-house, from tempering in robotic ovens to blade finishing, ensuring quality control across the whole production process.

Flat or tapered circular blades of all diameters required by all industries, shear cutting, pressure cutting or hot cutting.

Traditional and multiple bottom knives and bottom knives with Expando cutting ring.

We guarantee the availability of standard market size knives to meet Just-in-time supply needs.

Features

Benefits

of blades and counter-blades

manufactured each year

of which 1 fully robotic