Technical features

Benefits

Positioning

Manual positioning

The machine operator uses the pinion on the knife holder attachment to move the cutting unit. Precision is maximized through the use of a rack and pinion recirculating ball slider. In addition, the use of a pneumatic coupling piston allows the upper and lower units to be moved simultaneously without losing cutting geometries.

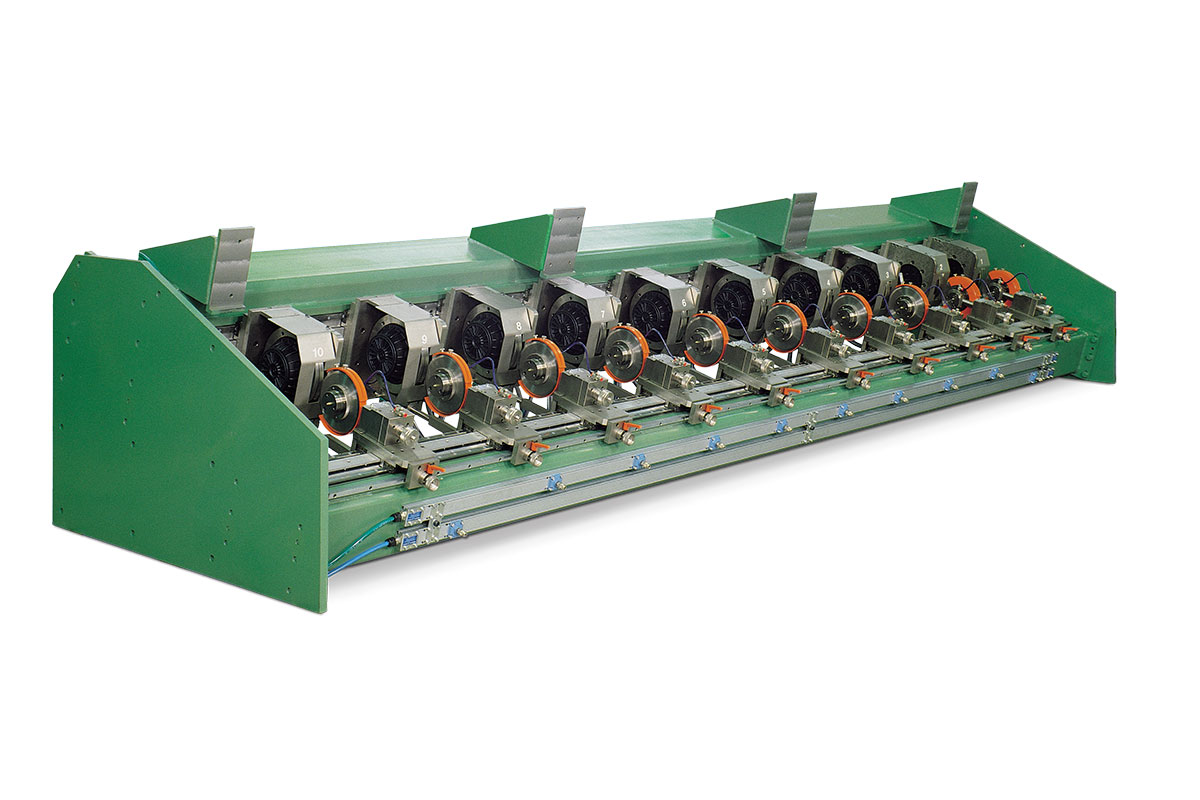

Automatic positioning

The positioning of this Mario Cotta cutting system is fully automatic. The operator will only interact with the Scada software, specially designed by Mario Cotta, by inputting, storing and recalling cutting recipes. The software and positioning system will then move all the units with the utmost speed and precision.

Web-Out Solution

The units are moved by belt-drive attachments located on each motor and by a belt driven by a brushless motor.

The use of a coupling piston allows the synchronized movement of the upper and lower units.

Web-in solution

The units are moved by belt-driven attachments positioned on each motor and each knife holder and by a belt driven by a brushless motor for positioning the knife holders and a belt driven by a brushless motor to position the motors.

This positioning thus allows for a change of cutting recipe, and consequent high-precision handling of the units, without a coupling piston, thus allowing the material to be kept in place in the cutting section without losing any cutting geometries.

Automatic simultaneous positioning

To decrease positioning time even more dramatically and reduce downtime, the simultaneous positioning solution meets this need. Each cutting unit is equipped with an independent positioning motor using a high-precision rack and pinion method. The independent positioning solution can be installed in either a Web-Out (a single travel motor per cutting unit) or Web-in version (dual travel motors, one for the knife holder and one for the motor)

Displayed positioning

Displayed positioning allows the operator to view, live on a monitor located in the cutting section, all the heights and positions of the knife holders he is handling. Handling remains manual, carried out by the machine operator, but the operator will be able to rely on high-precision MTS sensors and a 12-inch monitor to position the cutting units more quickly and accurately.