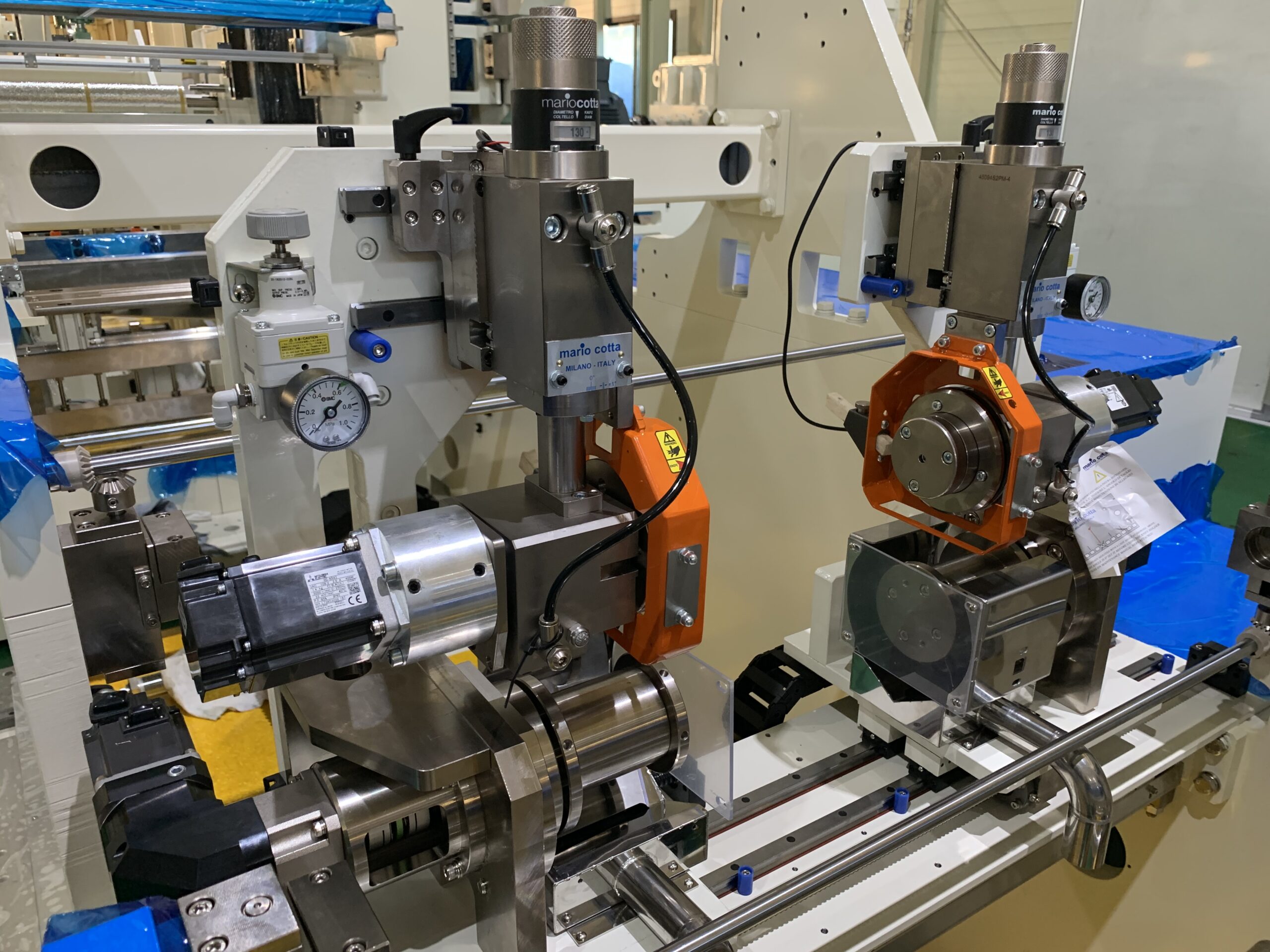

Metallic Films

Aluminum? Copper? Battery Foil? Laminated Metallic Films? The lowest common denominator for the above is the delicate nature of the material during cutting operations. Slitting systems should be designed to give the utmost adjustment flexibility and stability.

Where

How

Why

oursolutions

Aluminum? Copper? Battery Foil? Laminated Metallic Films? The lowest common denominator for the above is the delicate nature of the material during cutting operations. Slitting systems should be designed to give the utmost adjustment flexibility and stability.

How can we help you?

Please fill out the following contact form to request assistance or for general questions.

OR

Call us at +39 02 979661

Our offices will be happy to get back to you you to answer your questions

"*" indicates required fields