Technical features

Benefits

Solutions

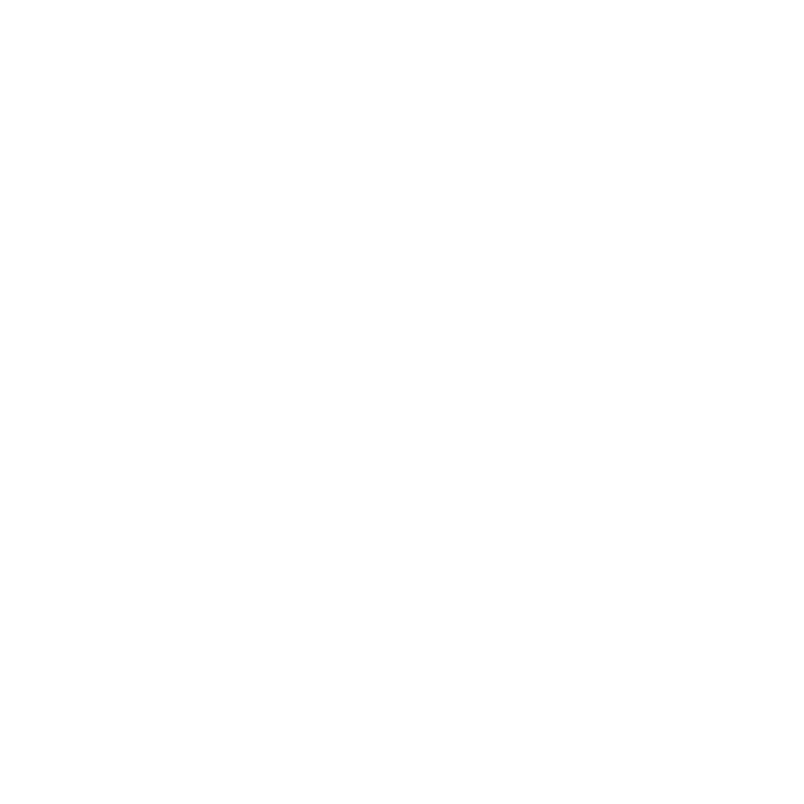

Expando Solution

o Expando by Mario Cotta is the next-generation solution for tangent shear shaft-driven systems. The Expando slitting system consists of an upper and a lower part, equipped with Mario Cotta high-performance pneumatic knife holders and bottom-knife expandable shaft. Blade changing is extremely quick and safe thanks to Mario Cotta’s patented Expando bottom knives; the use of a double-edged HSS cutting ring means that the expandable shaft does not have to be removed for blade changes, and there are no resharpening costs. The Expando slitting system is the best solution for speeds not exceeding 1800 m/min, and when a large number of cuts and narrow minimum cuts (25mm or above) are required.

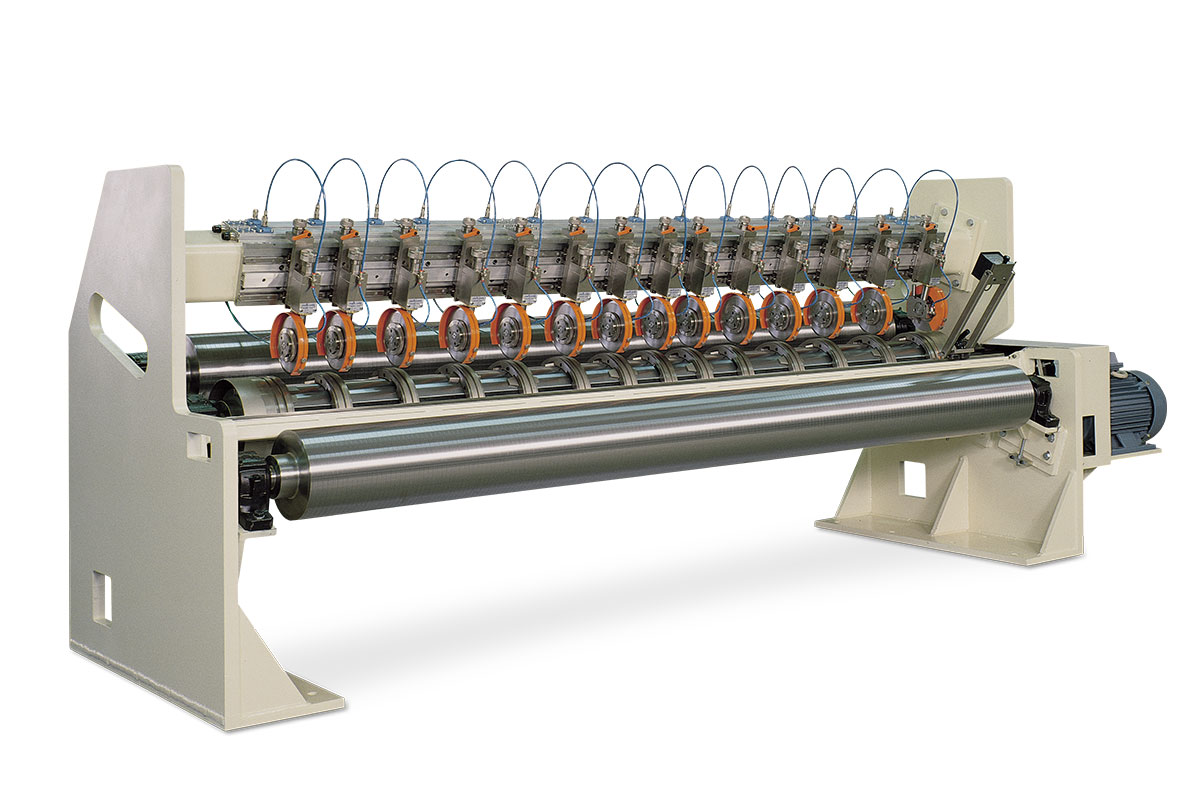

Multiple Bottom-knife solution

For those applications where storage cannot be provided for unused cutting units or where machine space does not allow a tangential layout of the slitting system, a multiple bottom-knife setup may be the best solution.

The bottom-knife holder shaft is fully equipped with multiple bottom-knives, also manufactured directly by Mario Cotta, based on drawings established and studied in concert with the engineering department to meet all recipe and minimum cut requirements.

Positioning

Manual positioning

The machine operator uses the pinion on the knife holder attachment to move the cutting unit. Precision is maximized through the use of a rack and pinion recirculating ball slider. In addition, the use of a pneumatic coupling piston allows the upper and lower units to be moved simultaneously without losing cutting geometries.

Automatic positioning

The positioning of this Mario Cotta slitting system is fully automatic. The operator will interact using only the proprietary Mario Cotta software, inputting, storing and recalling cutting formulas. The software and positioning system will then move all the units with the utmost speed and precision.

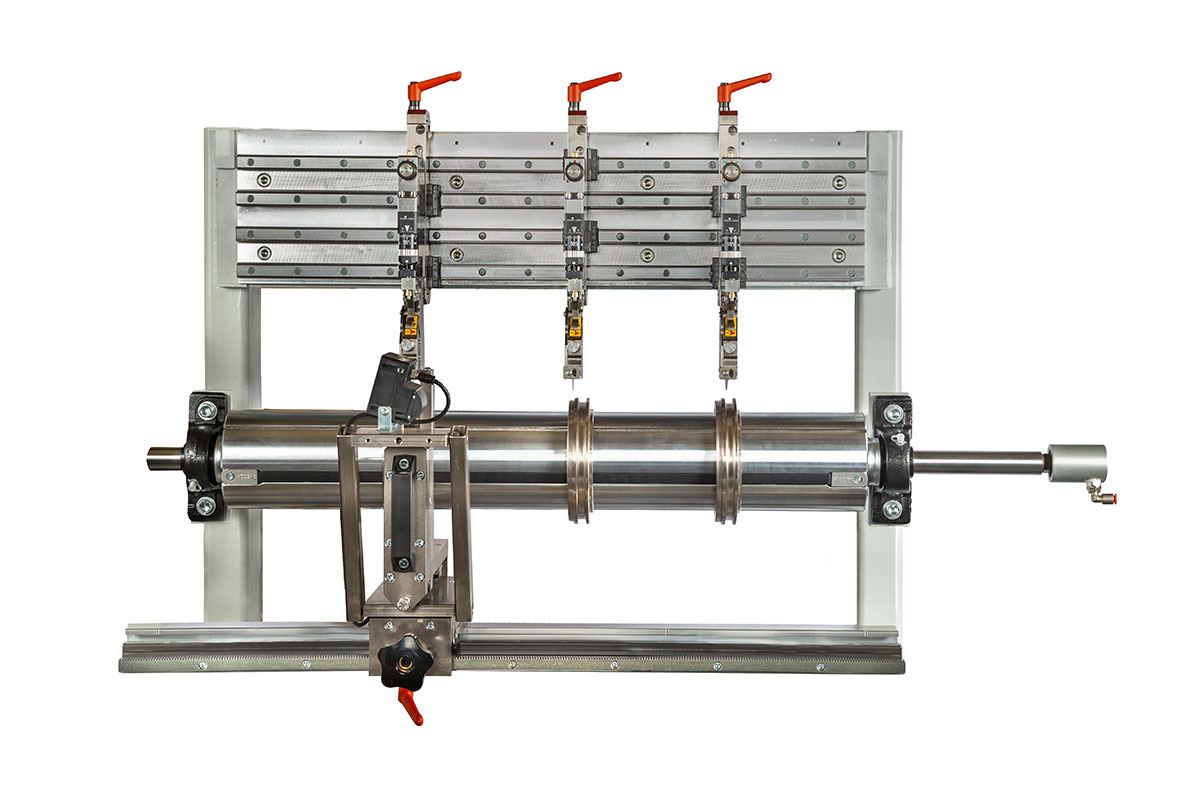

Web Out Solution

The units are moved by a carriage on a roll-on guide that moves the upper unit.

The use of a coupling piston allows the synchronized movement of the upper and lower units.

Web-In Solution

The units are moved by a dual carriage on roll-on guides that act independently on the top and bottom knife units. This positioning thus allows for a change of cutting recipe, and consequent high-precision handling of the units, without a coupling piston, thus allowing the material to be kept in place in the slitting section, maintaining all cutting values.

Positioning on display

A laser pointer with attached display of position is mounted on a guide, the operator is able to gauge the exact height to proceed with manual positioning of the cutting unit.

Manual positioning aided by the laser pointer and display unit allows the operator to speed up movements and consequently change formulas more quickly.